Lithium-ion batteries are crucial for our phones and cars because they store much energy. Energy density means how much power they can keep in a small space or weight. Knowing about energy density is important because it affects how well these batteries work, how long they last, and how we can use them in different things.

Part 1. What is the energy density of a lithium-ion battery?

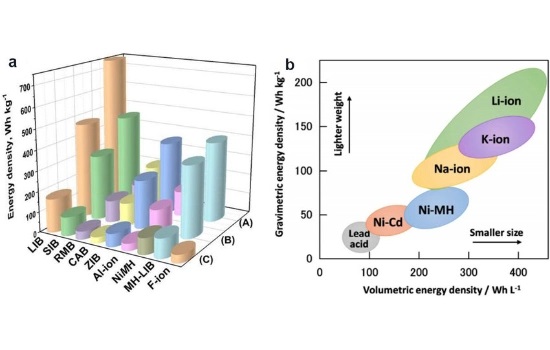

Energy density refers to how much energy can be stored per unit volume (Wh/L) or weight (Wh/kg) in a lithium-ion battery, making it a key factor in improving battery performance for mobile devices and electric vehicles (EVs). Typically expressed in watt-hours per liter (Wh/L) or kilogram (Wh/kg), it determines the power a battery can hold and subsequently deliver. High energy density signifies more incredible energy stored within a compact space or lighter weight, translating to longer-lasting, more powerful, and efficient batteries.

Average Energy Density Metrics

Lithium-ion batteries commonly exhibit energy densities ranging between 150 to 250 watt-hours per kilogram (Wh/kg) or 300 to 700 watt-hours per liter (Wh/L). However, technological advancements continue to push these boundaries, with newer iterations surpassing these conventional benchmarks.

Part 2. Influences on li-ion battery energy density

1. Electrode Materials

The type and composition of electrode materials, such as high-nickel cathodes (NMC, NCA) and silicon-based anodes, are critical in boosting the energy density of lithium-ion batteries. Innovations in these materials have led to the next generation of high-energy-density batteries for electric vehicles and smartphones.

Materials with higher specific capacities, such as high-nickel cathodes (NMC, NCA) and high-capacity anode materials like silicon or lithium titanate, tend to offer increased energy density potential. Researchers continuously explore and optimize these materials to balance energy density, stability, and cost-effectiveness.

2. Cell Design and Configuration

The design and architecture of lithium-ion battery cells significantly impact their energy density. Optimizing the arrangement of electrode layers, separator thickness, and the overall cell structure can influence the packing density of active materials, thereby affecting the energy stored within a given volume or weight.

3. Electrolyte Composition

The electrolyte, serving as the medium for ion transport between electrodes, impacts energy density. The choice of electrolyte affects the cell’s voltage stability, internal resistance, and safety. Research into solid-state electrolytes aims to increase energy density by replacing the liquid electrolyte while enhancing safety and longevity.

4. Packing Efficiency

The packing density and the efficiency of space utilization within the battery cell greatly influence energy density. Maximizing the active material content and minimizing inactive components such as binders and conductive additives contribute to achieving higher energy densities.

5. Temperature and Operating Conditions

Temperature significantly affects the performance and energy density of lithium-ion batteries. Extreme temperatures can impact the efficiency of ion movement, electrode reactions, and overall cell performance. Maintaining an optimal operating temperature range is crucial for achieving and preserving high energy density.

6. State of Charge and Cycling Behavior

The energy density of lithium-ion batteries can vary with the state of charge and the number of charge-discharge cycles. Cycling behavior, including depth of discharge and charging rates, can affect the degradation of active materials, impacting energy density over the battery’s lifespan.

Part 3. Types of lithium-ion batteries and their energy density

Lithium-ion vs. Lithium-Polymer

Lithium-ion batteries typically exhibit energy densities ranging between 150 to 250 watt-hours per kilogram (Wh/kg) or 300 to 700 watt-hours per liter (Wh/L). These batteries have extensive use in many applications owing to their relatively high energy density. They power smartphones, laptops, electric vehicles, and even grid storage systems due to their energy-to-weight and energy-to-volume ratios.

Lithium-polymer batteries, a subset of lithium-ion technology, have energy densities slightly lower than conventional lithium-ion variants. They typically range between 100 and 200 Wh/kg or 200 and 400 Wh/L. Despite their marginally reduced energy densities, their advantage lies in their flexibility, allowing for thinner and custom-shaped designs. This characteristic makes them suitable for applications where space and form factor flexibility are critical.

Lithium Iron Phosphate Battery(LiFePO4):

LiFePO4 batteries, while possessing slightly lower energy densities than conventional lithium-ion variants, usually range between 90 and 120 Wh/kg or 180 and 240 Wh/L. Their primary strength lies in their robust safety profile and longevity. These batteries are well-suited for applications where safety and stability are paramount, such as in power tools, medical devices, and stationary energy storage systems.

Other Lithium Batteries

Lithium-Sulfur Battery (Li-S):

Li-S batteries boast a theoretical energy density of up to 500 Wh/kg or higher, surpassing most traditional lithium-ion variants. However, practical implementations currently achieve energy densities ranging between 300 to 350 Wh/kg. Challenges related to sulfur cathode degradation and cycle life hinder their widespread commercialization.

Lithium-Air Battery (Li-Air):

Li-Air batteries exhibit remarkable theoretical energy densities surpassing 1000 Wh/kg. However, practical limitations related to electrolyte stability and electrode design have limited their real-world energy densities to experimental levels, currently achieving around 500 Wh/kg in research settings.

Lithium-Titanate Battery (Li4Ti5O12):

Li-Titanate batteries exhibit lower energy densities, typically between 70 and 100 Wh/kg or 100 and 150 Wh/L. However, they compensate with exceptional charge-discharge rates, long cycle life, and enhanced safety. These batteries find applications in scenarios prioritizing rapid charging, such as electric vehicles and grid storage systems requiring high power output.

Part 4. What is the future of lithium-ion battery energy density?

Recent advancements in solid-state batteries, new cathode materials, and improved manufacturing processes are expected to dramatically increase energy densities in the coming years, making future electric vehicles more efficient and smartphones with longer battery life. Researchers target energy densities of over 300 Wh/kg for mass-market lithium-ion batteries.