During the use of lithium-ion rechargeable batteries, overcharge, overdischarge, and overcurrent will affect battery life, performance, and safety. The fuse in the rechargeable battery acts as a secondary overcurrent protection in conjunction with the IC control loop to effectively monitor and prevent battery damage. Cause damage.

In recent years, with the miniaturization and popularization of mobile appliances, lithium-ion rechargeable batteries have the advantages of small size, light weight, high output voltage, stable discharge voltage, long storage time, etc., which has led to a dramatic increase in the amount of lithium-ion rechargeable batteries used in appliances.

Lithium-ion rechargeable batteries are one type of lithium batteries (rechargeable secondary batteries). Placing protective circuits in the batteries can effectively protect the battery from damage caused by overcharge, overdischarge, and overcurrent or improper use. As a overcurrent protection device, the fuse can protect the lithium ion rechargeable battery from damage due to large current and short circuit during charging or discharging.

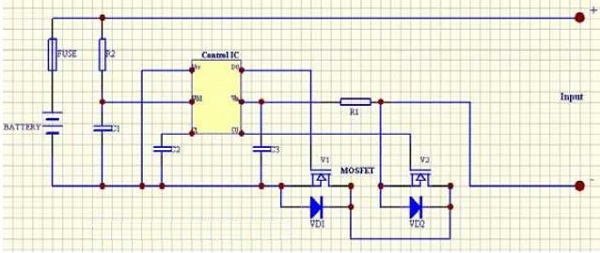

Here the following diagram (a typical lithium-ion rechargeable battery protection circuit diagram) is used as an example to illustrate the battery protection circuit and working principle:

typical lithium-ion rechargeable battery protection circuit diagram

This protection circuit consists of two MOSFETs and a control IC plus some RC components. The control IC is responsible for monitoring the battery voltage and controlling the gates of the two MOSFETs. The MOSFETs act as switches in the circuit and control the on and off of the charging and discharging circuits. Fuse is the secondary protection for the fuse, and C2 is Time-delay capacitor. This circuit has functions such as overcharge protection, overdischarge protection, overcurrent protection and short circuit protection.

1). Normal working status

During normal charging and discharging, the C0 and D0 pins of the control IC in the circuit are high, and V1 and V2 are both on. The charging current flows from the input, charges the battery through the fuse, and flows from input- after V1 and V2. During normal discharge, the current flows to the negative electrode of the battery through input- and V2 and V1, and its current direction is opposite to the charging current direction. Since the on-resistances Rds (ON) of V1 and V2 are very small, the current consumption in this state is uA level, so the losses are very small.

2). overcharge protection

The battery is charged with constant current at the initial stage of charging. As the charging time increases, the battery voltage will also rise. During this process, when the IC detects that the battery voltage reaches the overcharge detection voltage (the value is determined by the control IC), C0 The pin changes from high voltage to low voltage, so that the gate of the MOSFET that controls charging is turned off, that is, V2 turns from on to off to cut off the charging circuit, so that the charger cannot protect the battery. Overcharge detection corresponds to pulse charging and malfunction due to noise. It is necessary to set a delay time. The delay time is determined by C2 and is generally set to about 1 second.

3). over discharge protection

Over-discharge protection stops discharging the load when the battery voltage becomes low. When the battery discharges to the load, its voltage gradually decreases with the discharge process. When the battery voltage drops below the over-discharge detection voltage, its capacity is completely discharged. If the battery continues to discharge, it will cause permanent damage to the battery. Therefore, when the control IC detects that the battery voltage is lower than the over-discharge point detection voltage, its D0 pin changes from a high voltage to a low voltage, turning V1 from on to off to cut off the discharge circuit, and the battery cannot continue to discharge for protection. effect. Because the battery voltage cannot be lowered below the over-discharge detection voltage, the control IC must consume very little current. Overdischarge detection corresponds to pulse charging and malfunction due to noise. The delay time that needs to be set is generally about 100 ms.

4). over current protection and short circuit protection

Overcurrent protection is to stop discharging the load when consuming large current. The purpose of this function is to protect the battery and MOSFET and ensure the safety of the battery under working conditions. During the normal discharge process, the current flows through the two MOSFETs because the on-resistance will generate a voltage across the two ends. This voltage value is U = I * [R1ds + R2ds], where the turned-on V1 and V2 are regarded as resistance, that is, R1ds and R2ds. At this time, if the load causes an abnormal increase in the loop current due to some reason, when the current increases so that the voltage also increases to the voltage value determined by the control IC, the D0 pin of the control IC quickly changes from a high voltage to a low voltage. Turn off V1 to cut off the discharge loop, and the loop current becomes zero. The delay time to be set is generally about 13 ms. When the voltage increases to the voltage value determined by the control IC (at this time the IC judges that the load is short-circuited), V1 will turn from on to off, and its working principle is similar to overcurrent protection. The short-circuit protection delay time is generally less than 7 microseconds. If the current continues to increase in the event of an accident, the fuse will act as a secondary protection during overcurrent to avoid permanent damage to the control IC and MOSFET in the circuit.

The working principle of the lithium-ion rechargeable battery protection circuit has been described in detail above. In addition to the control IC and MOSFET, there is another important component in the circuit, which is the fuse. It plays a secondary overcurrent protection role in the circuit. Because of its resistance, The small amount of energy consumed in the circuit is negligible, so this has become the main reason for many battery manufacturers to consider replacing PTC polymers (excessive internal resistance) with new multilayer ceramic chip fuses.